the study

Published September 26, 2024 Author

Anna Goldie and Azaria Mirhoseini

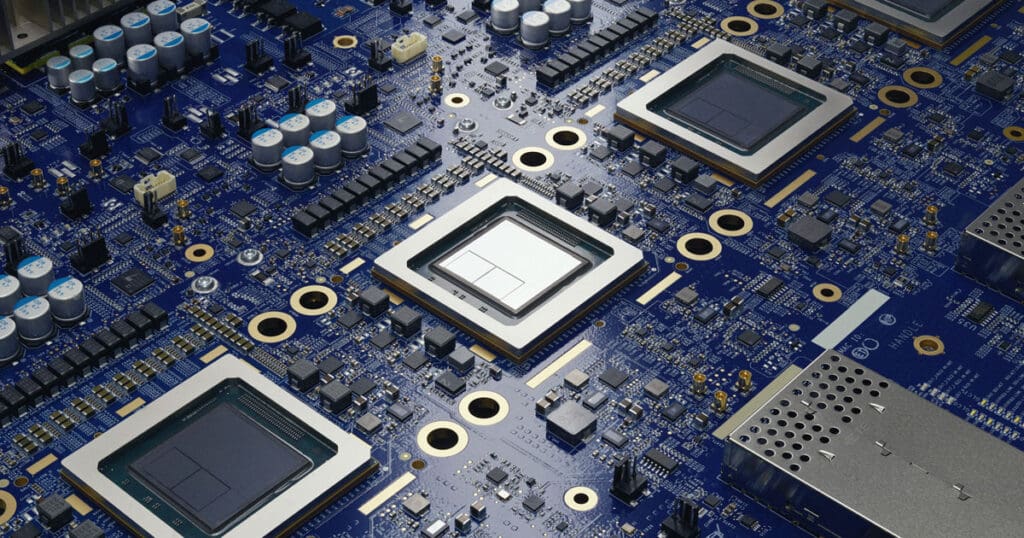

Our AI methods accelerate and optimize chip designs, and our superhuman chip layouts are used in hardware around the world.

In 2020, we released a preprint introducing new reinforcement learning techniques for designing chip layouts. It was later published in Nature and made open source.

Today, we are publishing an appendix in Nature detailing our method and its impact on the chip design field. We also release pre-trained checkpoints, share the model weights, and announce its name: AlphaChip.

Computer chips are driving remarkable advances in artificial intelligence (AI), and AlphaChip is responding to the benefits by using AI to accelerate and optimize chip designs. This technique has been used to design superhuman chip layouts in the past three generations of Google’s custom AI accelerators, Tensor Processing Units (TPUs).

AlphaChip was one of the first reinforcement learning approaches used to solve real-world engineering problems. It generates superhuman or equivalent chip layouts in hours, without weeks or months of human effort, that can be used in chips around the world, from data centers to mobile phones. has been.

“

AlphaChip’s breakthrough AI approach revolutionizes critical stages of chip design.

SR Tsai, Senior Vice President, MediaTek

How AlphaChip works

Designing a chip layout is not an easy task. Computer chips are made up of many interconnected blocks with layers of circuit components, all connected by incredibly thin wires. There are also many complex and intertwined design constraints that must all be met at the same time. Because of its complexity, chip designers have struggled to automate the chip floorplanning process for more than 60 years.

Similar to AlphaGo and AlphaZero, which learned to master the games of Go, Chess, and Shogi, we built AlphaChip to approach chip floorplanning as a kind of game.

AlphaChip starts with an empty grid and places circuit components one at a time until all components are placed. You will then be rewarded based on the quality of your final layout. A new “edge-based” graph neural network allows AlphaChip to learn relationships between interconnected chip components and generalize across chips, allowing AlphaChip to improve each layout it designs.

Left: Animation showing AlphaChip deploying an open source Ariane RISC-V CPU with no prior experience. Right: Animation of AlphaChip placing the same block after practicing with 20 TPU-related designs.

Using AI to design Google’s AI accelerator chips

AlphaChip has produced the superhuman chip layout used in every generation of Google’s TPUs since its introduction in 2020. These chips make it possible to massively scale up AI models based on Google’s Transformer architecture.

TPUs are at the heart of our powerful generative AI systems, from large-scale language models like Gemini to image and video generators like Imagen and Veo. These AI accelerators are also at the core of Google’s AI services and are available to external users via Google Cloud.

Cloud TPU v5p AI accelerator supercomputers lined up in Google data centers.

To design the TPU layout, AlphaChip first practices various chip blocks from previous generations, including on-chip and cross-chip networking blocks, memory controllers, and data transport buffers. This process is called pretraining. Next, run AlphaChip on the current TPU block to generate a high-quality layout. Unlike traditional approaches, AlphaChip gets better and faster as it solves more instances of chip placement tasks, similar to what human experts do.

With each new generation of TPUs, including the latest Trillium (6th generation), AlphaChip accelerates the design cycle by designing better chip layouts and offering more overall floorplans. , which has produced more high-performance chips.

Bar chart showing the number of chip blocks for AlphaChip designs across three generations of Google’s Tensor Processing Units (TPUs), including v5e, v5p, and Trillium.

Bar chart showing average wire length reduction for AlphaChips across three generations of Google’s Tensor Processing Units (TPUs) compared to placements produced by the TPU physical design team.

AlphaChip’s broader impact

AlphaChip’s impact can be seen through applications across Alphabet, the research community, and the chip design industry. In addition to designing specialized AI accelerators like TPUs, AlphaChip has also produced layouts for Alphabet’s other chips, including the Google Axion processor, the company’s first Arm-based general-purpose data center CPU.

External organizations are also adopting AlphaChip and building on it. For example, MediaTek, one of the world’s top chip design companies, has expanded AlphaChip to accelerate the development of cutting-edge chips while increasing power, performance, and chip area.

AlphaChip has sparked an explosion of research on AI for chip design, which has been extended to other important stages of chip design, such as logic synthesis and macro selection.

“

AlphaChip has inspired a whole new field of research in reinforcement learning for chip design, across design flows from logic synthesis to floorplanning, timing optimization, and more.

Professor Siddharth Garg, New York University Tandon School of Engineering

Creating the chip of the future

At AlphaChip, we optimize every step of the chip design cycle, from computer architecture to manufacturing, and create custom hardware chip designs used in everyday devices such as smartphones, medical equipment, and agricultural sensors. I believe that it has the potential to transform

Future versions of AlphaChip are currently in development. We look forward to working with the community to continue revolutionizing this field and delivering a future where chips are even faster, cheaper, and more power efficient.

Acknowledgment

We are very grateful to our wonderful co-authors: Mustafa Yazgan, Joe Wenjie Jiang, Ebrahim Songhori, Shen Wang, Young-Joon Lee, Eric Johnson, Omkar Pathak, Azade Nazi, Jiwoo Pak, Andy Tong, Kavya Srinivasa, William Hang, Emre Tanser, Kwok V. Lee, James Loudon, Richard Ho, Roger Carpenter, Jeff Dean.

We particularly wish to thank Joe Wenjie Zhang, Ebrahim Songhori, Yongjun Lee, Roger Carpenter, and Sergio Guadarrama for their continued efforts to bring their influence to this production, as well as Kuok V. We are especially grateful to Mr. Lee for his research advice and guidance, and to senior author Jeff Dean for his assistance and assistance. Deep technical discussion.

We would also like to thank Ed Chi, Zoubin Ghahramani, Koray Kavukcuoglu, Dave Patterson, and Chris Manning for their advice and support.